In recent years, the advent of fiber laser technology has revolutionized the manufacturing and fabrication industries. Among the various fiber laser options available, the 30W fiber laser stands out for its impressive capabilities and versatility. With a combination of precision, efficiency, and cost-effectiveness, the 30W fiber laser is transforming the way businesses approach cutting, engraving, and marking operations. In this article, we will explore the core functionalities of 30W fiber lasers, their applications across different sectors, and the numerous benefits they offer to manufacturers.

Enhancing Precision and Efficiency in Manufacturing with 30W Fiber Laser Technology: A Comprehensive Overview of Applications and Benefits

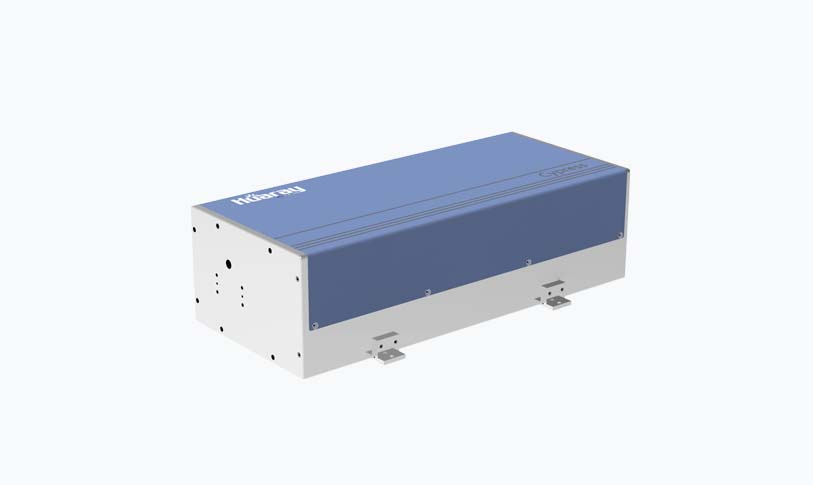

Understanding 30W Fiber Laser Technology

Fiber lasers generate a highly focused beam of light by using solid-state technology. The “30W” designation refers to the power output of the laser, which directly impacts its cutting and engraving capability. A 30W fiber laser is ideal for various materials, including metals, plastics, and even some types of glass, making it an invaluable tool for a wide range of manufacturing environments.

Enhancing Precision and Efficiency in Manufacturing with 30W Fiber Laser Technology: A Comprehensive Overview of Applications and Benefits

The technology relies on optical fibers doped with rare-earth elements like ytterbium to amplify the light, ensuring high efficiency and superior beam quality. This feature minimizes energy consumption while maximizing output power and performance. Additionally, fiber lasers have a narrower wavelength beam compared to CO2 lasers, enhancing their cutting capabilities on thin materials.

Applications of 30W Fiber Lasers

1. **Metal Cutting and Engraving**: The 30W fiber laser is particularly renowned for its ability to cut through thin metals, including stainless steel, aluminum, and copper. Its precision ensures clean edges and minimal heat-affected zones, which is critical for intricate designs.

2. **Marking and Etching**: Businesses utilize 30W fiber lasers for permanent marking and etching. The technology allows for high-speed marking on metal surfaces, producing crisp, high-contrast codes, logos, and serial numbers that resist wear over time. This application is vital in industries like aerospace, automotive, and electronics, where traceability is essential.

3. **Jewelry Making**: The jewelry industry benefits significantly from 30W fiber laser technology. It allows jewelers to create detailed engravings and intricate designs on various metals, including gold, silver, and platinum. These applications enable customization and personalization, meeting consumer demands for unique products.

4. **Medical Device Manufacturing**: In the medical sector, precision is paramount. 30W fiber lasers are employed to produce intricate components for medical devices, ensuring that dimensions adhere to stringent regulatory standards. Their precision and cleanliness help in maintaining high levels of sterility in the manufacturing process.

5. **Signage and Branding**: With the growing demand for customized signage, the use of 30W fiber lasers in the production of signs, nameplates, and branding elements has surged. The technology enables high-speed, accurate marking on a variety of materials, including plastics, woods, and metals, appealing to businesses aiming for professional presentation.

Benefits of Utilizing 30W Fiber Lasers

1. **High Efficiency**: The energy efficiency of fiber lasers is a significant advantage, resulting in lower operational costs compared to traditional laser systems. The solid-state design minimizes energy loss, which is particularly beneficial for high-volume production settings.

Enhancing Precision and Efficiency in Manufacturing with 30W Fiber Laser Technology: A Comprehensive Overview of Applications and Benefits

2. **Minimal Maintenance**: Fiber lasers have fewer moving parts compared to other laser types, resulting in reduced maintenance requirements and longer lifespans. This reliability ensures consistent performance and minimizes downtime for manufacturers.

3. **Versatility**: The ability to work with a wide range of materials, from metals to plastics, makes the 30W fiber laser an incredibly versatile tool. This adaptability allows businesses to switch between different projects seamlessly without needing multiple machines.

4. **Precision and Quality**: The concentrated beam produced by a 30W fiber laser not only enhances cutting speeds but also ensures that the quality of the cut or mark remains at a high standard, giving manufacturers a competitive edge.

5. **Compact Design**: The compact nature of fiber laser systems allows for flexible installation in various manufacturing environments. They can be easily integrated into existing workflows without requiring extensive spatial modification.

Conclusion

In conclusion, the 30W fiber laser presents a transformative solution for manufacturers seeking to enhance their productivity and efficiency across multiple applications. With its precision, versatility, and cost-effectiveness, this laser technology is paving the way for innovations in various industries. As businesses continue to integrate advanced manufacturing technologies, the 30W fiber laser stands out as a pivotal tool that is sure to drive growth and success in the future. Whether for cutting, engraving, or marking, the benefits of this remarkable technology cannot be overlooked.femtosecond pulsed laser