In recent years, the manufacturing industry has seen a remarkable transformation driven by the advent of advanced technologies. Among these innovations, fiber laser systems have emerged as a crucial player that enhances productivity, precision, and versatility across various applications. This article aims to delve deep into the workings, advantages, applications, and future prospects of fiber laser systems, illustrating why they are becoming indispensable tools in modern manufacturing processes.

Exploring the Revolutionary Advancements in Manufacturing Through the Use of Fiber Laser Systems: Efficiency, Precision, and Versatility

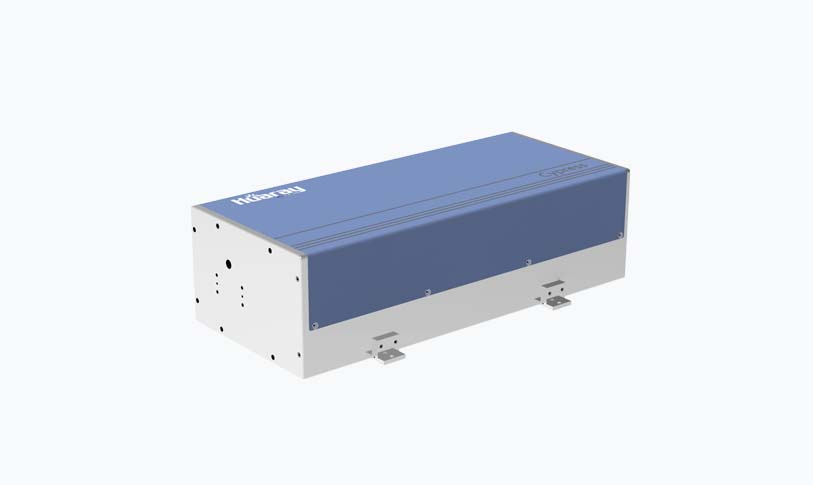

At the core of fiber laser technology lies its unique structure, which employs a fiber-doped medium to generate a laser beam. Unlike traditional laser systems that utilize gas or solid-state mediums, fiber lasers utilize glass fibers that are infused with rare-earth elements, such as ytterbium. This results in a highly efficient, compact machine that can produce high-quality beams with remarkable power density and beam quality. The ability to deliver such concentrated energy makes fiber laser systems ideal for a wide range of cutting, welding, engraving, and marking processes.

One of the primary advantages of fiber laser systems is their exceptional efficiency compared to other laser technologies. They convert a higher percentage of electrical energy into laser output, resulting in lower operational costs and reduced energy consumption. This energy efficiency not only helps manufacturers cut down expenses but also supports sustainability initiatives by lowering the carbon footprint associated with production processes.

In terms of precision, fiber laser systems offer high-quality cuts with narrow kerfs and minimal heat-affected zones. This level of precision is particularly crucial in industries where tolerances are tight and quality is paramount. For example, the automotive and aerospace sectors rely heavily on fiber laser systems for cutting and welding components where even minor inaccuracies can lead to catastrophic failures. Additionally, these systems can work on various materials, including metals, plastics, and ceramics, allowing manufacturers to meet diverse production requirements.

Versatility is another hallmark of fiber laser systems. They can be easily adapted for multiple tasks, making them a valuable asset in a manufacturing environment. This adaptability means that a single fiber laser machine can be used for cutting intricate designs, engraving detailed patterns, and marking products with serial numbers or logos. This flexibility leads to reduced downtime and increased production efficiency, as manufacturers can switch between different tasks without needing to change equipment.

Furthermore, advancements in fiber laser systems have paved the way for automation and integration with computer-aided design (CAD) and computer-aided manufacturing (CAM) software. This integration allows for seamless transitioning from design to production, facilitating quicker turnaround times and enhancing overall workflow efficiency. Manufacturers can produce complex designs with ease, which is particularly beneficial in industries requiring rapid prototyping or custom pieces.

Another significant aspect to consider is the ongoing development in fiber laser technology. Innovations such as multi-beam fiber lasers and high-power single-mode lasers are pushing the boundaries of what these systems can achieve. Multi-beam lasers can split a single beam into multiple beams, allowing for simultaneous cutting of different components, thereby boosting productivity. High-power single-mode lasers are particularly suited for thicker materials, expanding the range of applications fiber laser systems can handle.

Exploring the Revolutionary Advancements in Manufacturing Through the Use of Fiber Laser Systems: Efficiency, Precision, and Versatility

Despite all these benefits, the adoption of fiber laser systems may require a certain level of investment, which can be a barrier for some smaller manufacturers. However, the long-term advantages, including operational efficiency, maintenance savings, and the ability to remain competitive in an increasingly demanding market, often outweigh the initial costs.

Exploring the Revolutionary Advancements in Manufacturing Through the Use of Fiber Laser Systems: Efficiency, Precision, and Versatility

In conclusion, fiber laser systems represent a significant leap forward in manufacturing technology. Their efficiency, precision, and versatility make them ideal for a wide array of applications, from cutting and welding to engraving and marking. As they continue to evolve, fiber lasers are set to play an even more pivotal role in the future of manufacturing, paving the way for smarter, faster, and more sustainable production processes. Businesses that invest in fiber laser systems are not only ensuring their current success but are also positioning themselves to thrive in a rapidly changing industrial landscape.laser co2 treatment cost