****

In the world of modern technology, precision and speed are paramount, particularly in fields such as manufacturing, laser engraving, and even medical applications. Among the multitude of tools engineered to meet these demands, galvo mirror scanners stand out for their unique ability to manipulate laser beams with remarkable accuracy and speed. These devices utilize galvanometer motors to control mirrors and direct lasers, making them indispensable in various applications. In this article, we will explore the workings of galvo mirror scanners, their functionalities, advantages, and their diverse applications across different industries.

Exploring the Innovative Applications and Advancements of Galvo Mirror Scanners in Modern Technology

Exploring the Innovative Applications and Advancements of Galvo Mirror Scanners in Modern Technology

Understanding Galvo Mirror Scanners

At the heart of the functionality of galvo mirror scanners is their core component: the galvanometer. A galvanometer is an electromechanical device that can detect and measure electric current. In the context of a galvo scanner, it converts electrical signals into precise angular movements of reflective mirrors. This ability to direct laser beams rapidly enables the scanner to trace complex designs onto surfaces at lightning speeds.

Typically, a galvo mirror scanner consists of two mirrors positioned at right angles to each other. The first mirror directs the laser beam horizontally, while the second mirror adjusts the vertical positioning. By rapidly altering the angles of these mirrors, the scanner can accurately direct a laser beam across a defined workspace. The result is a high-speed, high-precision engraving or material processing tool capable of executing intricate patterns with ease.

Advantages of Galvo Mirror Scanners

One of the primary benefits of using galvo mirror scanners is their speed. Traditional laser systems, which move the entire laser assembly to work on a series of points, can take substantial time for complex engravings or cutting tasks. In contrast, galvo scanners can execute several hundred movements per second, significantly reducing processing time.

Another notable advantage is precision. The accuracy of galvo systems is often measured in microns, allowing for intricate designs that would be challenging or impossible to achieve with less advanced technology. This level of precision makes galvo scanners particularly valuable in industries requiring fine detail, such as the jewelry or medical sectors.

Additionally, the design of galvo systems allows for a compact form factor. The elimination of moving parts like rails or stages results in a more streamlined setup that not only saves space but also reduces wear and tear. This durability translates into lower maintenance costs over time.

Diverse Applications of Galvo Mirror Scanners

Galvo mirror scanners are finding applications across a multitude of industries. One of the most common uses is in **laser engraving**. Artists and manufacturers employ these machines for engraving designs on various materials, including wood, glass, and metal. The ability to swiftly produce high-quality engravings has revolutionized custom products, from personalized gifts to industrial components.

In the **pharmaceutical and medical industries**, galvo scanners have found their niche in **medical device manufacturing**. They are crucial in the production of components such as bone screws or other intricate medical instruments, where precision is non-negotiable. The scanners ensure that products meet stringent regulatory standards while enhancing production efficiency.

Exploring the Innovative Applications and Advancements of Galvo Mirror Scanners in Modern Technology

Furthermore, in the field of **automotive manufacturing**, galvo mirror scanners facilitate **cutting and marking** applications. Their ability to cut through various materials allows automotive manufacturers to produce parts with complex geometries efficiently.

The **electronic industry** also leverages galvo scanners for the precision marking of circuit boards and components. The speed and accuracy offered by these scanners help manufacturers enhance production rates while maintaining quality standards.

Conclusion

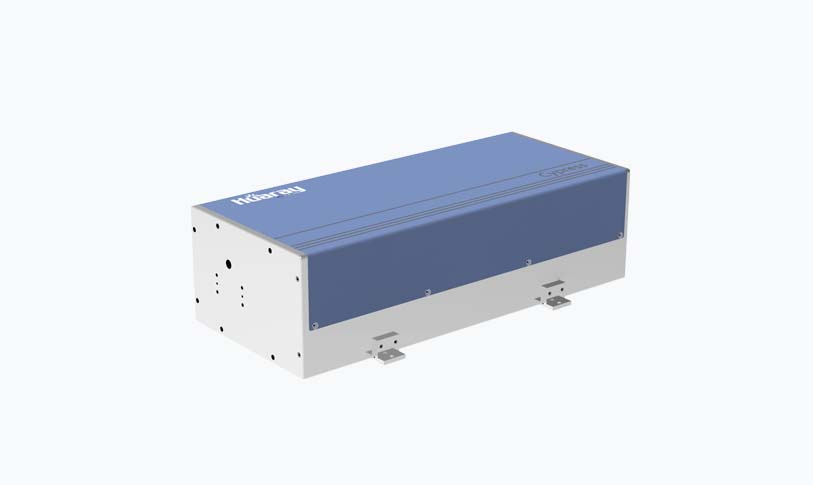

The advent of galvo mirror scanners has undeniably transformed multiple industries by offering rapid, high-precision laser manipulation capabilities. As technology continues to evolve, the functionality and efficiency of these devices are set to expand further. With ongoing research and development, we can expect to see even more innovative applications emerge, solidifying the galvo mirror scanner’s place as a cornerstone in modern manufacturing and design. As industries increasingly demand faster turnaround times without compromising quality, the role of galvo mirror scanners will likely become even more critical in meeting these challenges head-on. Whether in art, medicine, or high-tech manufacturing, the future of galvo mirror scanners is indeed bright.50w mopa fiber laser