Oval Tube | Laser Cutting Solution – Full Technology of Oval Tube Steel Processing

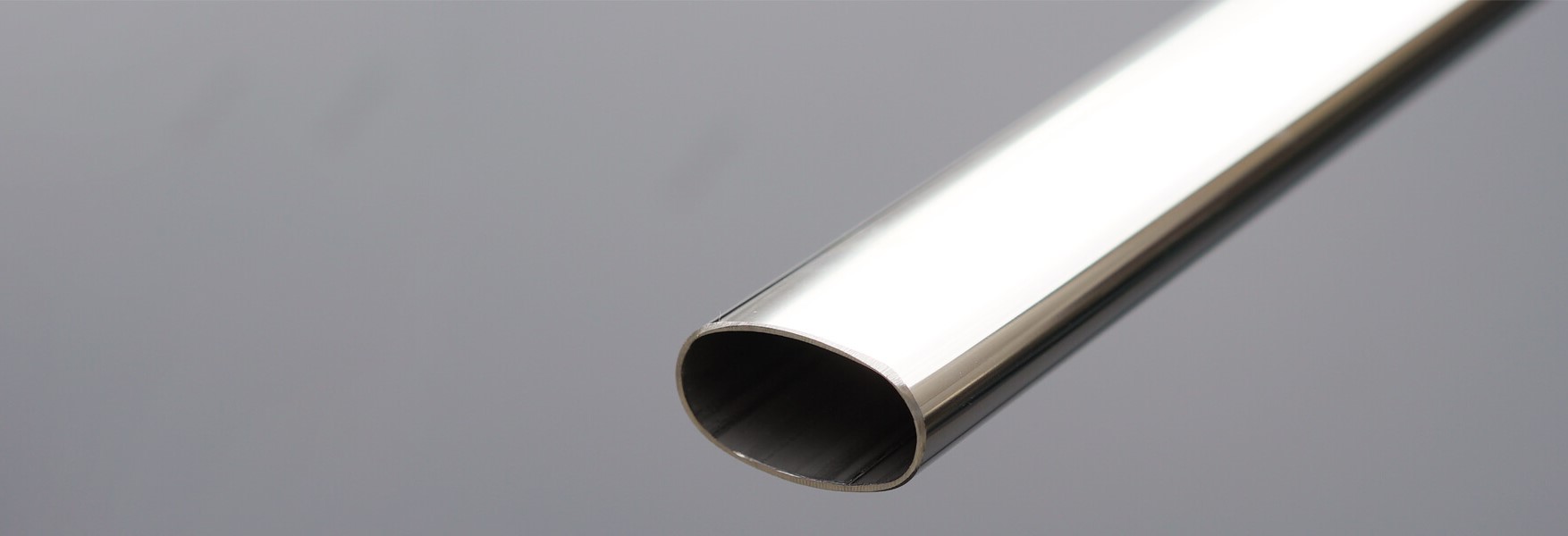

What is Oval Tube and Type of Oval Tubes?

Oval Tube is a kind of special-shaped metal tubes, according to the different use, it has different shape oval tube, such as elliptical steel tubes, seamless elliptic steel pipes, flat elliptic steel pipes, galvanized elliptic steel pipes, tapered elliptic steel pipes, flat elliptic steel pipes, regular elliptic steel pipes and various complex cross-section steel mechanical properties of elliptic steel tubes. Precision steel tubes of any size with a thickness of 1mm-30mm.

From the Materials, it including aluminium oval tube, steel oval tube, stainless steel oval tube and so on.

The Use of Oval Tube?

Oval Tube is widely used in automobile industry for oval tube exhaust, decoration, transportation facilities, airport construction, bridge support, three-dimensional garage, outdoor advertising, fitness equipment, cosmetic applications such as D.O.T. guardrails, wind power equipment, vehicle manufacturing, and other industries.

What the Advantage of Oval Tube?

1. From the outer surface layer, two layers of hot-dip galvanizing and spray paints are used to prevent corrosion. The inner surface layer is made of seamless steel pipes with protruding inner ribs and polypropylene plastic pipes through unique processing technology.

2. The elliptical tube is hard and has a certain degree of softness. It is not easy to be deformed by extrusion and is resistant to impact. The installation reliability is high, and there is no embrittlement under the gas and sunlight.

3. Weather resistance and compression resistance. Heating pipe operating temperature: 0°C~75°C, the temperature reaches 95°C in a moment, pressure≤1.5MPa; cooling water pipe operating temperature: 0°C~55C, pressure≤2.0MPa.

4. Strong thermal insulation and corrosion resistance. It is suitable to be buried in the dark but also can be installed in the dark.

5. Clean up non-toxic, healthy, and safe. Various performance parameters have met the requirements of the quality standards of the Ministry of Health.

6. The inner cavity is smooth and clean, does not rust, does not accumulate, and the total flow rate is 25%-30% larger than the metal hose with the same nominal diameter. There is no pipe diameter damage at the coupling.

7. Unique processing technology is selected. The convex net-like structure pattern is produced and processed in the inner cavity of the seamless steel pipe, which greatly increases the sliding friction between the surface metal hose and the inner plastic hose.

In turn, the inconsistency of thermal deformation between the inner and outer pipes is reasonably reduced. The thermal expansion coefficient of the elliptical pipe is 2.5×(1/100000)/°C, and the service life is 5 times that of the hot-dip galvanized steel pipe.

8. The installation is convenient and reliable. The tube is connected by quick-release wallboard connectors, which do not require threading, saving time and effort.

The Large-diameter square tube has a very common application area, because its wall thickness is too thick, so it can bear a lot of working pressure. Generally, it can be used as the raw material of hollow parts, used for bearing force and critical pipeline applications.

In fact, it can be used as structural tubes for airlines, crude oil geological exploration pipes, and petrochemical equipment pipes. When square steel pipes are used, they must also comply with relevant policies and regulations. Therefore, different main uses require the application of relatively different specifications and models of pipelines. This also shows a key prerequisite for the application of elliptical pipes, especially When transporting more risky and flammable substances, it is necessary to find seamless steel pipes of suitable specifications and models, so that safety accidents can be reasonably avoided.

How to Produce the Oval Tubes?

The key to the production process lines in the type of product. From raw materials to finished products, a series of technological processes must be passed. The whole process of this processing technology must be carried out with a variety of industrial equipment, electric welding, electrical control systems, and inspection equipment. Various types of machinery and equipment have a variety of effective layouts according to different production process regulations.

1. Typical steps of high-frequency welded tube: uncoiling-hot-rolled strip flattening-end and end cutting-hot-rolled strip butt welding-looper discharge -Forming-Electric welding-Removal of burrs-Die-Flaw detection-Fly cutting-Initial inspection-Seamless steel pipe straightening-Pipe section production and processing-Pressure test-Flaw detection-Copying and coating-Finished products.

2. Seamlessly spliced elliptical steel tube is also called elliptical steel pipe, which is a production process of seamless pipe.

3. The bending method of stainless steel elliptical tube generally adopts the cam principle method. The result of how many times the cam principle method is used to process the thin-walled stainless steel elliptical tubes with multiple arcs is the result of many verifications. Everyone has heard of the cam. The camshaft rotates, the follower is connected to the cam contour, and the follower makes reciprocating motion.

According to this principle: as long as 5 arcs are designed on a mold, and the length of the center layer of each arc is equal to the length of the center layer of the product arc (because the R on the mold with larger rebound is smaller than the R on the product), The mold is the center of the arc with a large included angle as the center of rotation. The driven part uses a cylinder. Because of the compressibility of the gas and the pressure relief valve can be used to adjust the pressure, if the bending pressure is large, you can use the double force cylinder. , The cylinder rod is connected to the curved roller seat, and there is a guide rail under the roller seat. The key factors that affect the wrinkling of the oval tube are the bending speed and the lining material of the oval tube.

How to control the bending speed? The proportional flow valve can be used to control the forward and backward speed of the main cylinder. When the bending radius R of the object is small, the speed control should be appropriate.

How to Cut the Oval Tubes into Yur Demanded Products?

According to the different cutting demands, you might use manual cutting or automatic cutting methods. And using the different cutting methods the cost will very different. Such as sawing machine will cut off the tube but can’t hollowing on the tube, tube cutter also a small tool for small tube cutting.

If you want more high efficiency and no limited cutting design cutting machine, then a fiber laser tube cutting machine will be your best choice.

Why Tube Laser Cutting Machine is Your Best Choice to Process Oval Tube?

Metal Laser Cutting is an un-touch high temperature and high-speed cutting method, there is no distortion during the cutting, the accuracy reaches 0.1mm, can cut any shape on your oval tube’s surface. Perfect laser cutting result on aluminium oval tube, steel oval tube, stainless steel oval tube and so on.

Golden Laser is one of the leading tube laser cutting machine manufacturers in China, right supplies a full laser cutting solution for the Oval Tubes process. Below is the analysis of our customer use tube laser cutting machine for their oval tubes cutting , maybe you also have the same oval tube exhaust cutting demand as him.